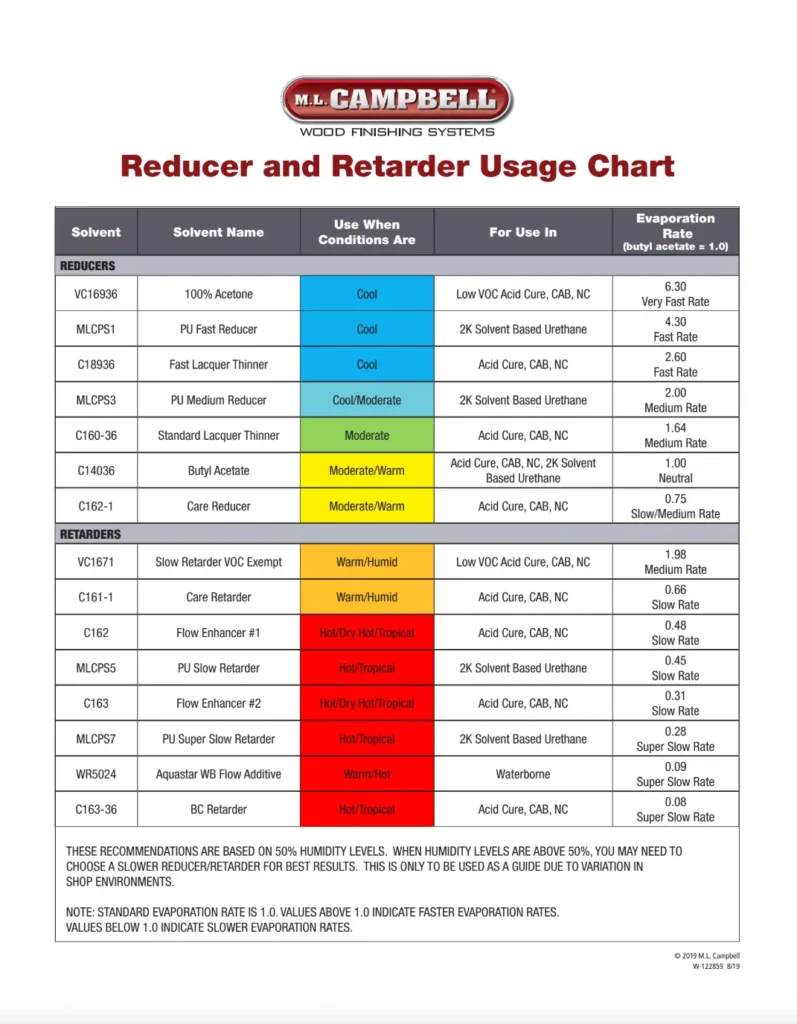

When spraying finishes like acid cure, CAB, or 2K solvent-based urethane, picking the wrong reducer or retarder can lead to trouble. You might end up with runs, dry spray, or poor flow. The secret to great results? Always match your reducer or retarder to your shop’s temperature and humidity.

Cool temps? Go with fast evaporating options like Fast Lacquer Thinner or PU Fast Reducer for smoother flow.

Warm and humid? Slow Retarder VOC Exempt or Care Retarder will keep your finish open longer.

Hot or dry conditions? PU Super Slow Retarder helps prevent dry spray and ensures a silky smooth finish.

These insights come straight from M.L. Campbell’s Reducer and Retarder Usage Chart, and they’ll help you spray like a pro.

The Best Time to Apply Industrial Coatings

Temperature and humidity can make or break your finish. Here’s a quick guide to when and what to spray:

Cool Weather (Below 65°F):

-

Use fast reducers to avoid slow drying and blushing.

-

Products like Fast Lacquer Thinner (C18936) or PU Fast Reducer (MLCPS1) are great choices.

Moderate Conditions (65°F–80°F):

-

Balanced reducers like Standard Lacquer Thinner (C160-36) work well.

-

They provide ideal leveling without drying too quickly.

Hot/Tropical (Over 80°F or Low Humidity):

-

Slow or super slow retarders reduce flashing and prevent dry spray.

-

Try PU Super Slow Retarder (MLCPS7) or BC Retarder (C163-36) for the best results.

Humidity over 50%? Always consider a slower reducer or retarder. High moisture can cause blushing or uneven finishes.

Pro tip: Check the weather forecast or use a digital hygrometer to plan your spraying days!

Solvent Speeds Make a Difference

Evaporation rate matters. Here’s how some popular solvents stack up, based on the M.L. Campbell chart (where Butyl Acetate = 1.0):

-

VC16936 – 100% Acetone: 6.30 (Very Fast Rate)

-

MLCPS1 – PU Fast Reducer: 4.30 (Fast Rate)

-

C18936 – Fast Lacquer Thinner: 2.60 (Fast Rate)

-

C162-1 – Care Reducer: 0.75 (Slow/Medium Rate)

-

C161-1 – Care Retarder: 0.66 (Slow Rate)

-

C163-36 – BC Retarder: 0.08 (Super Slow Rate)

Slower solvents give you more open time for leveling and blending. Faster solvents dry quickly and help avoid sagging in cooler weather.

Avoid These Common Finishing Mistakes

Using the wrong reducer or retarder can lead to costly rework. Here’s what to watch for:

-

Dry Spray: Happens in hot, dry conditions if solvents evaporate too fast.

-

Blushing: Moisture trapped under the finish, common in humid weather.

-

Runs and Sags: Occur when solvent is too slow in cooler temps.

-

Poor Flow or Orange Peel: Often caused by mismatched solvent speed.

Fix issues before they happen by choosing the right product for your climate and finish type.

We’re Here to Help!

Choosing the perfect coating system or additive doesn’t have to be confusing. At The Color House, our experts will help you:

-

Pick the right reducer or retarder for your shop’s conditions

-

Avoid common finishing problems

-

Achieve a smooth, professional finish every time

Let’s make your next job faster, smoother, and longer-lasting!